|

Getting your Trinity Audio player ready...

|

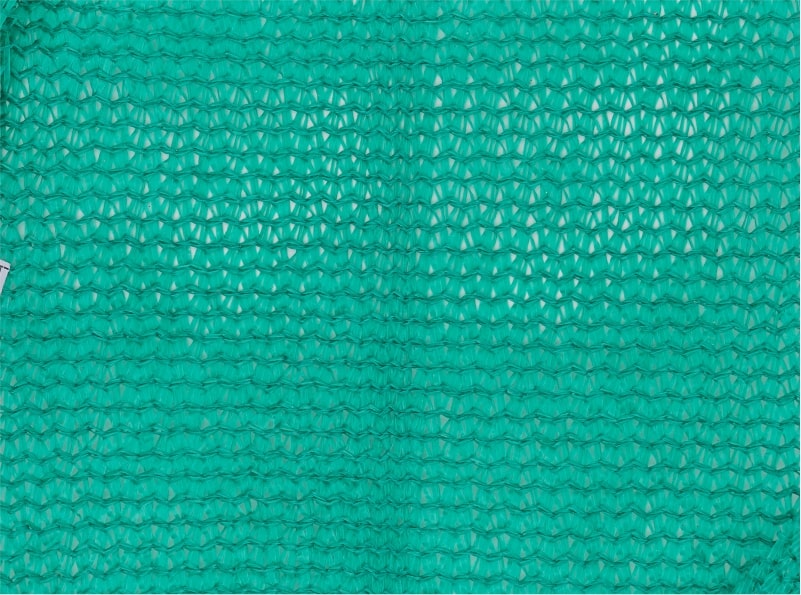

The construction industry is constantly evolving, integrating innovative solutions to enhance safety, efficiency, and environmental sustainability. At the forefront of this green revolution is the use of green nets for construction, a simple yet powerful tool that is transforming how we approach building projects. This comprehensive guide will help you delve deeper into the world of green nets, exploring their types, functionality, and the multitude of benefits they offer.

What are Green Nets and their Primary Purpose

Table of Contents

- 1 What are Green Nets and their Primary Purpose

- 2 Types of Green Nets for Construction Applications

- 3 Materials Used in Manufacturing Green Nets

- 4

- 5 1. High-Density Polyethylene (HDPE) – The Core Material

- 6 2. UV Stabilizers – For Sun Protection

- 7 3. Additives for Flexibility and Longevity

- 8 4. Mesh Pattern & Knotting Technology

- 9 How Green Nets Work

- 10 What are the Applications of Green Nets in Construction

- 11 1. Safety from Falling Debris

- 12 2. Dust and Pollution Control

- 13 3. UV Protection for Workers and Materials

- 14 4. Wind and Weather Resistance

- 15 5. Compliance with Safety Regulations

- 16 Safety Benefits

- 17 Conclusion

Green nets for construction are a specialised, eco-friendly mesh used to safeguard construction sites. Its primary purpose is to protect workers and pedestrians from debris, manage dust emissions, and reduce environmental impact. The Indonet Group, with its commitment to safety and sustainability, manufactures these nets as a vital tool for modern construction sites.

Types of Green Nets for Construction Applications

There are several types of green nets that cater to various construction needs:

Debris Nets: These are fine-meshed, robust nets capable of catching even small debris, ensuring a clean and safe environment below the construction site.

Scaffold Nets: These are crucial for scaffold structures, providing a shield against falling tools and materials and ensuring the safety of those working at heights.

Shade Nets: Particularly beneficial in hot climates, these nets offer a respite from the harsh sun, reducing heat stress and boosting worker productivity.

Wind and Dust Nets: These specialised nets mitigate the effects of wind, controlling dust dispersion and maintaining visibility and air quality at the construction site.

indonet Group provides a range of green nets, catering to diverse construction demands.

Materials Used in Manufacturing Green Nets

1. High-Density Polyethylene (HDPE) – The Core Material

The primary material used in most green nets is HDPE (High-Density Polyethene). Known for its strength, flexibility, and resistance to environmental damage, HDPE is the backbone of construction-grade green nets.

Why HDPE?

Excellent tensile strength

Lightweight yet highly durable

Resistant to moisture and chemicals

Non-reactive to UV rays (when treated)

2. UV Stabilizers – For Sun Protection

Since green nets are often used in outdoor construction environments, they need to withstand prolonged exposure to sunlight. UV stabilizers are added during the manufacturing process to prevent degradation and maintain the net’s strength over time.

Benefits:

Increases the life of the net under direct sunlight

Prevents brittleness and colour fading

Makes the net ideal for hot climates like India

3. Additives for Flexibility and Longevity

To enhance performance, additional polymer additives are included in the mix:

Antioxidants—Prevent material degradation

Plasticisers – Improve flexibility

Anti-static agents – Reduce dust accumulation

4. Mesh Pattern & Knotting Technology

Although not a raw material, the knitting technique or mesh pattern significantly affects the quality and application of the net. Indonet’s green nets are manufactured using advanced warp-knitting or Raschel technology to ensure:

Uniform mesh size

High tear resistance

Better airflow while blocking debris

How Green Nets Work

Green nets used at construction sites serve multiple roles:

- Preventing Debris and Dust from Falling Off

Green nets are pivotal in ensuring construction safety and cleanliness. By wrapping the construction sites, particularly in high-rise projects, they trap and contain debris and dust, mitigating the risks of accidents and environmental contamination.

- Reducing Heat Stress and Improving Worksite Safety

Shade nets, a specialised form of green nets, significantly reduce heat stress on construction sites. By providing a cooler environment, they improve worker safety and efficiency, which is a key concern in the often harsh conditions of construction sites.

- Environmental Benefits

The use of green nets signifies a commitment to environmental protection in construction. They help in reducing pollution, controlling waste, and promoting sustainable construction practices, aligning with global environmental goals.

- Economic Advantages

Green nets offer substantial economic benefits. Their durability means less frequent replacements. Additionally, their efficiency in maintaining safer work environments reduces the risk of potential accidents, making them a cost-effective solution for construction projects.

What are the Applications of Green Nets in Construction

Green nets are versatile and find application in various construction scenarios, including high-rise buildings, bridges, and residential and commercial projects. Their adaptability makes them suitable for a wide range of construction environments.

1. Safety from Falling Debris

One of the primary applications of green nets is to prevent debris or construction material from falling onto workers or passersby. They create a protective barrier that reduces the risk of injury and ensures site safety, especially in urban high-rise projects.

2. Dust and Pollution Control

Green nets help contain construction dust, reducing its spread into surrounding environments. This plays a vital role in:

Complying with local environmental norms

Reducing air pollution on-site

Creating a cleaner, safer atmosphere for workers

3. UV Protection for Workers and Materials

Quality green nets from Indonet are designed to offer UV protection, which shields both workers and sensitive building materials (like cement, paint, and adhesives) from excessive sun exposure during hot summer months.

4. Wind and Weather Resistance

In open construction zones, green nets can act as a windbreaker, offering moderate protection against strong winds or light rain, making the site more workable during unstable weather conditions.

5. Compliance with Safety Regulations

Many regulatory bodies now mandate the use of safety nets in high-rise and commercial construction. Using Indonet green nets ensures compliance with these norms while providing durability and long-term performance.

Safety Benefits

The safety advantages of green nets are paramount. They play a crucial role in preventing injuries on site and protecting property, aligning with Indonet Group’s focus on safety as a top priority in construction.

Conclusion

Adopting green nets in construction projects is a step towards a more secure, clean, and sustainable future. Indonet Group’s advocacy for these nets underlines their importance in modern construction practices, making them an essential component for any environmentally conscious and safety-oriented construction project.

About Author

Indonet Group is a leading manufacturer and supplier of extruded plastic netting and geosynthetic solutions. With a strong commitment to quality and sustainability, Indonet serves industries ranging from agriculture to infrastructure, offering innovative and durable products. Backed by advanced technology and a customer-centric approach, Indonet Group continues to be a trusted name in the field, delivering excellence across global markets.

Follow the Expert